Biofine’s technology is demonstrated at the B2P2 Pilot Plant located at the University of Maine-Forest Bioproducts Research Institute-Technology Research Center

in Old Town, Maine.

The Biofine process, invented by Dr. Stephen W. Fitzpatrick, is widely recognized as one of the most efficient methods to convert lignocellulose to high-value bio-products. In 1999 Dr. Fitzpatrick was recognized for his discovery with the Presidential Green Chemistry Award. Since then, Biofine has developed its technology and expanded its patent portfolio to prepare for commercial deployment.

The Biofine Process

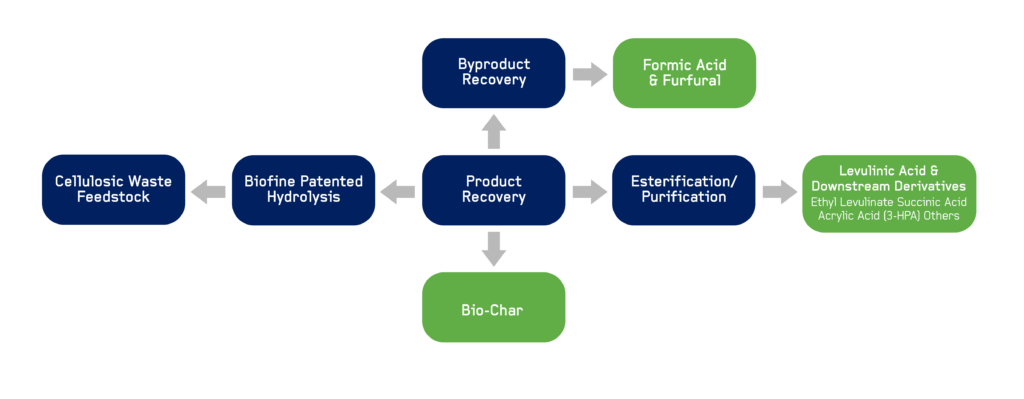

The Biofine process is a high temperature, dilute acid-catalyzed, rapid hydrolysis of lignocellulosic biomass. The patented reactor configuration refines biomass feed into four products: levulinic acid, formic acid, furfural, and a biochar that can used to produce energy. These products can then be further refined into downstream biofuels and chemicals with multi-billion dollar markets.

Biofine’s technology has been verified by third-party engineers as one of the most environmentally friendly technologies around. In fact, this next-generation technology can be run as a completely self-contained, closed-loop process by transforming transform non-food, cellulosic waste into value products while at the same time producing enough energy to power the plant via biochar.

Downstream conversion enables the production of numerous high-value chemical and fuel products.